The focus of the PERFECT-3D Division is 3D-printed ceramic tooling in support of investment castings. The primary products are ceramic cores, molds, and filters.

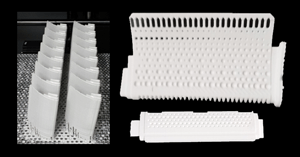

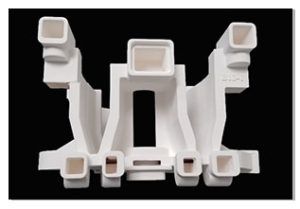

With the latest advances in 3D-printing, PERFECT-3D has developed patent-pending techniques to directly 3D-print ceramic molds for the casting of high temperature nickel-based alloys as well as steel and aluminum. This enables the foundry to bypass many of the front-end steps involved in the manufacture of castings, especially the lead time and cost to create the tooling for cores and wax patterns.

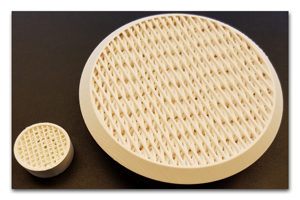

With the need for controlled flow rates in casting, PERFECT-3D has developed patent-pending techniques for printing ceramic filters for pour cups and runners.

Contact us to learn more about Renaissance Services PERFECT-3D Additive Manufacturing.