The Renaissance Services A-Team will be storming into the heart of Oklahoma for the Tinker and The Primes aviation maintenance tradeshow the first week of August 2024.

The event takes place from August 5 through August 8 at the Reed Conference Center in Midwest City, OK, minutes north of Tinker AFB and minutes east of downtown Oklahoma City.

Nearly 2,000 aerospace officials, agents, and military and civilian leaders attended the 2023 event, and we are excited for this year’s turnout.

A USAF B1-B Lancer bomber comes in for a landing at Tinker AFB in 2017. Building 3001 is where workers-built hundreds of aircraft during World War Two. Credit: USAF

Tinker AFB is home to the Oklahoma City Air Logistics Complex. It provides depot maintenance on the C/KC-135, B-1B, B-52 and E-3 aircraft, expanded phase maintenance on the Navy E-6 aircraft. Additionally, it provides maintenance, repair, and overhaul of F100, F107, F108, F110, F118, F119, F135 and TF33 engines for the Air Force, Air Force Reserve, Air National Guard, Navy, and foreign military sales.

The mechanics, technicians, and engineers of the Oklahoma City Air Logistics Complex handle maintenance, repair, and overhaul of many Air Force and Navy airborne accessory components. They also take care of the development and sustainment of operational flight programs, test program sets, automatic test equipment, and industrial automation software. They are responsible for the sustainment of many older but worthy aircraft and engines.

How does Renaissance Services (RSI) fit in?

RSI is a pioneer in manufacturing innovation. This includes 3D-printed ceramic molds, foundry filters, and related tooling for rapid and inexpensive castings for legacy aircraft and other military equipment. Many older warbirds are still serviceable and capable of performing missions. However, many of the manufacturers who made parts for these aircraft have gone out of business, and it is not cost-effective to reverse-engineer permanent molds for making a handful of replacement parts.

RSI’s experts and technicians can reverse-engineer and 3D-print one-use ceramic molds and related tooling to make such castings. They also ensure the castings become finished parts with properties and dimensions that make them as good or better than original manufactured parts.

These are examples of parts RSI has made for USAF aircraft using 3D-printed ceramic molds to make castings, then finished parts.

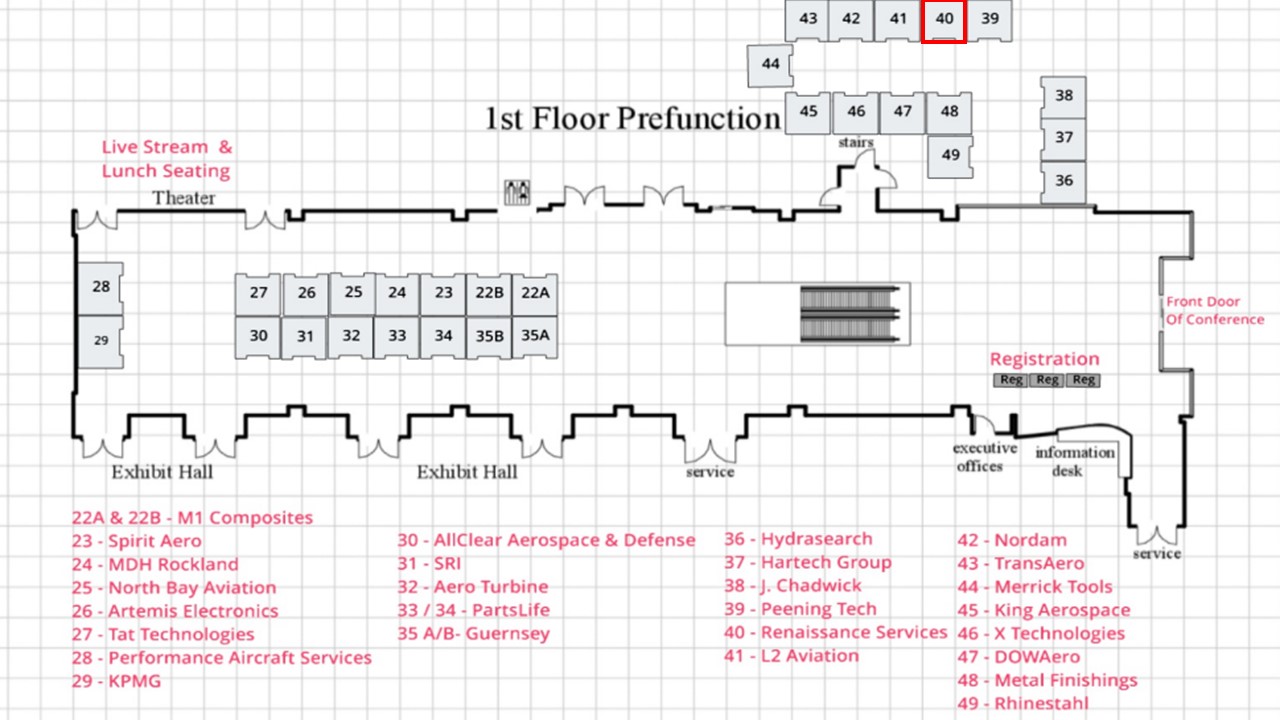

Rapid manufacture of mission-critical parts is Renaissance Services’ reason for being. The engineers of RSI’s A-team will be manning Booth 40 at this year’s Tinker and The Primes confab (check out our location via the map below), and they will be more than happy to meet with customers in need of rapid cast parts.

Please contact us directly to learn more about how Renaissance Services and their PERFECT-3D division can support your needs.

To learn how ceramic additive manufacturing can work for you, contact Rick Pressley at:

Renaissance Services Inc.

1 Herald Square

Fairborn, Ohio 45324

937-322-3227

[email protected]