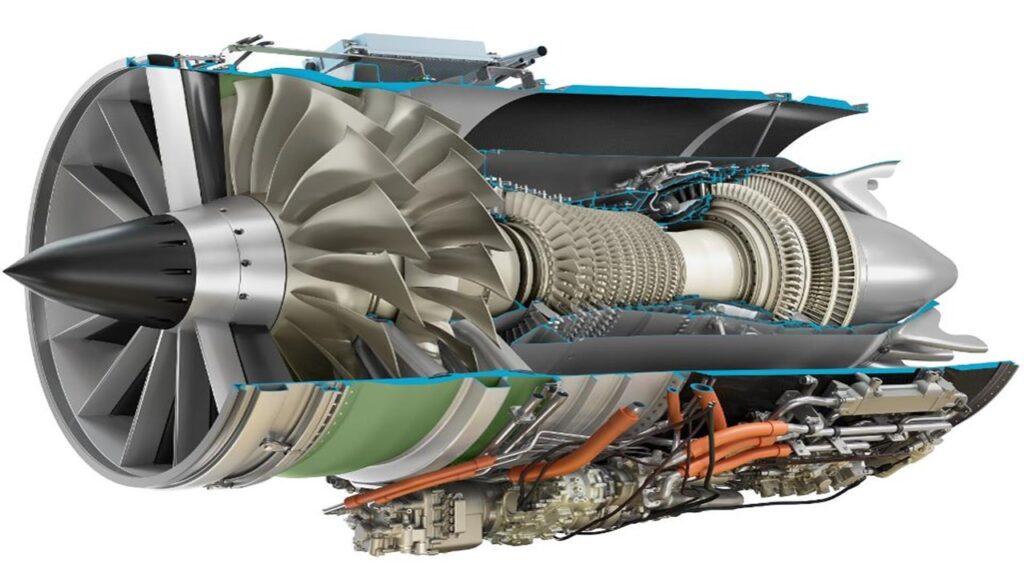

Renaissance Services will have a strong presence at this year’s Turbine Engine Technology Symposium (TETS), which is being held September 9th to 12th at the Dayton Convention Center. Renaissance Services and its additive manufacturing division, PERFECT-3D, will be exhibiting advanced turbine engine tooling and parts at the TETS conference. Additionally, Dan Sokol, Renaissance Services managing partner, will be presenting the results from one of the Air Force-funded R&D efforts in using ceramic additive manufacturing to make complex turbine engine components.

TETS is a biennial forum for the US turbine engine community to review and discuss the latest advancements in turbine engine technology. The theme for this year’s symposium is “Propulsion in the Era of Great Power Competition.” As global powers strive to maintain and expand their influence, advancements in turbine technology have become a critical factor in both military and civilian sectors.

The symposium will bring together experts from industry, academia, and government to explore cutting-edge developments, share insights, and discuss the implications of these advancements on national security and global stability.

Renaissance Services is at the forefront of technology and innovation, and the TETS review committee has invited Mr. Sokol to present his treatise, “Additive Manufacturing to Enable Low-Cost Cast-In Cooling for Turbines.” During the presentation, Mr. Sokol will provide greater insight into how Renaissance Services is leading an America Makes program with specific focus on leveraging additive manufacturing to make tooling for production of advanced castings. One objective of the program is the development of methods for ceramic 3D-printing to be used in production of cast-in cooling holes to dramatically lower the cost of cooled airfoils. You won’t want to miss this presentation, so mark your calendar as Mr. Sokol is scheduled to present on September 11th, from 3:30 to 4:00pm.

The photo above shows the finished 10-inch diameter Cooled Integrally Vaned Rotor with cast-in cooling holes. Renaissance Services team members designed and 3D-printed the ceramic mold for the hub, the 32 airfoil molds/cores, and related tooling to enable rapid production of this advanced part.

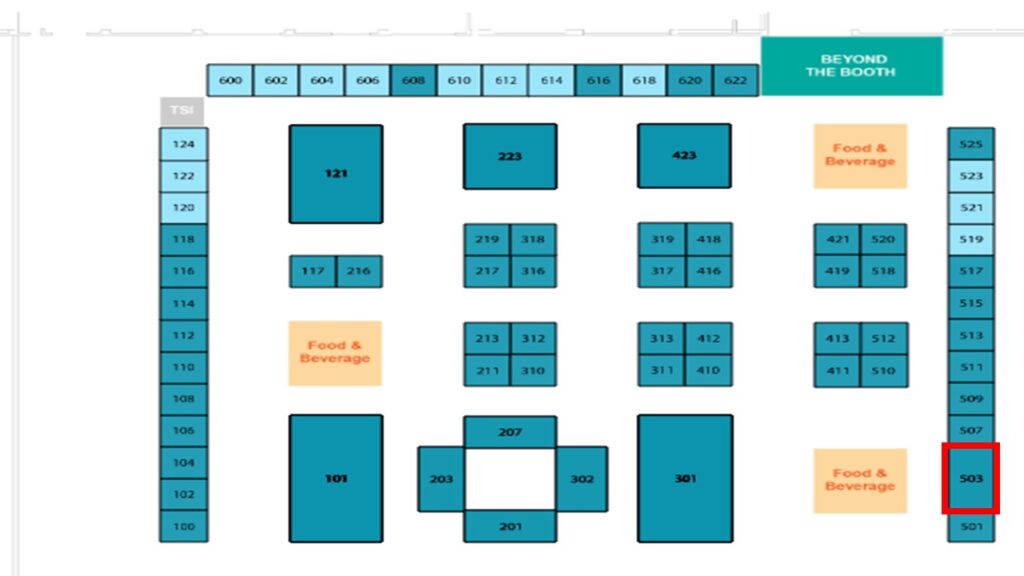

If you’re unable to make the presentation, then swing by Booth 503 (check out our location via the map below), and one of the Renaissance Services’ representatives will be more than happy to discuss your needs in greater detail.

Please contact us directly to schedule a time to meet at the Turbine Engine Technology Symposium or to learn more about how Renaissance Services and the PERFECT-3D division can support your needs.