Renaissance Services people put on a good show in one of the nation’s top venues –the Defense Manufacturing Conference in Nashville — two weeks before Christmas 2023. They brought good news about additive manufacturing and said the Renaissance booth was hopping with convention goers seriously looking for help.

Some AC-130 Spooky gunships are still on active duty. This aircraft, an armed variant of the venerable C-130 transport aircraft, and thousands of other legacy aircraft can use replacement parts that Renaissance Services can reverse-engineer and make quickly. Credit: USAF

“There was a lot of traffic” at the Renaissance Services booth, Director of Programs Rick Pressley said. “We were inundated with folks at our booth.”

Among those who dropped calling cards or personal info at the booth, Pressley said, were members of the U.S. Air Force, the U.S. Army, the U.S. Navy, agents of NAVAIR and NAVSEA, agents of the Defense Logistics Agency, and many representatives of corporations large and small. He said these people “were folks we had cards from.”

A number of “folks were bringing (us) problems,” Pressley said. He elaborated they were seeking legacy hardware and were happy to find out about Renaissance Services’ products and services.

“They were very interested in our product (and services),” the veteran additive manufacturing engineer recalled. He said they appreciated Renaissance can “take it all the way from reverse engineering to finished product.”

Pressley gave an address at the trade show about rapid production of legacy parts. He said his presentation, “Rapid Production of Legacy Cast Parts Using 3D-Printed Ceramic Molds” was well-received.

Pressley noted roughly 60 people attended his lecture, and there were a number of solid questions from the audience. The Renaissance Services exec also noted there were several attendees who stayed after his presentation to ask him questions in private about additive manufacturing and Renaissance Services’ capabilities.

The veteran AM engineer said Renaissance Services’ presentation also tweaked the unique perspective of another attendee. He said the individual asked him, more or less, “Why are you only doing work for the Air Force? Couldn’t you be helping the Army and the Navy too?”

Nashville Skyline. Credit: U.S. National Park Service

Pressley said he assured the person Renaissance Services is always ready, willing, and able to assist the other branches of the Service, and civilian customers too.

Don Deptowicz, a veteran engineering and manufacturing consultant who also carried the flag for Renaissance Services at the trade show, had a similar take in terms of what attendees were looking for.

Deptowicz, who advises Renaissance Services on advanced programs, said his impressions, in talking with people who came by the Renaissance Services booth and who talked with him at other times during the confab, included these:

- Parts availability continues to deteriorate across all industries.

- Lack of castings and forgings are resulting in reduced capability in machining and post-treatment facilities.

- The entire manufacturing supply train must be treated as an integrated system for maximum efficiency. (A chain holds; a train moves.)

- Loss of “tribal knowledge” is not being addressed across the OEMs and customer base.

- There does not appear to be a recognizable pre-emptive strategy to contain and correct the industry base today.

An F-15 Eagle fighter pilot and two F-16 Falcon fighter pilots fly their warbirds thru the sky. Both types of fighters have been in the USAF arsenal for decades.

Credit: USAF

Deptowicz noted reps from several large aviation industry manufacturers – including some firms whose people seem to scan trade shows for info from the exhibitors without doing business with them — were willing to identify themselves and talk with him because their companies are also in need of manufacturing and reverse engineering help. Deptowicz said a lot of industries are suffering a “parts apocalypse” and their key people, out of necessity, are starting to search for different answers to their manufacturing problems. He said several agents of these large aviation industry manufacturers made repeat visits to the Renaissance Services booth during the trade show.

But the Christmas/Hanukkah season conference was hardly a gloomy occasion. The Renaissance Services team came to the trade show to provide solutions to the convention goers’ problems. Pressley and Deptowicz did what they could to help the attendees with their legacy parts manufacturing needs.

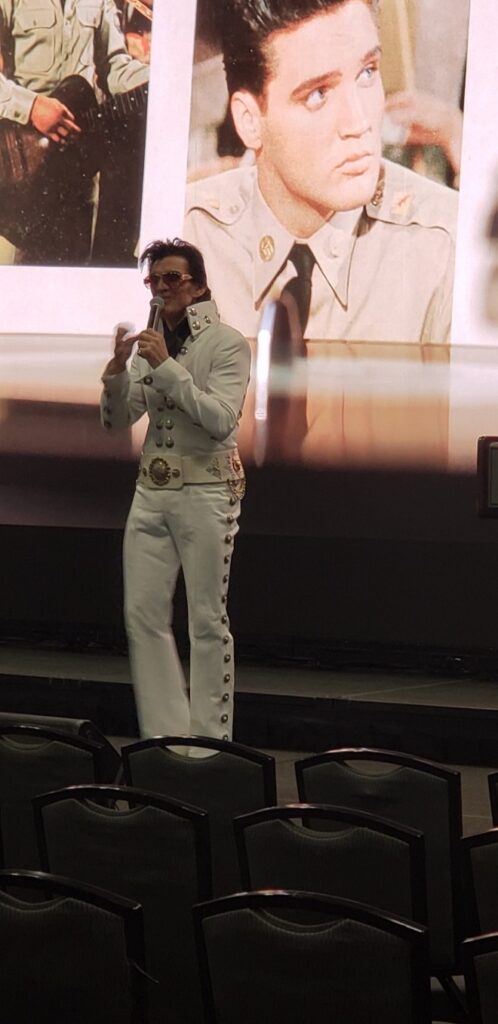

“Elvis” is in the Building.

Credit: Rick Pressley

And what is a Nashville event without a Music City sighting or two? Pressley noted an Elvis impersonator was in the building and was near the Renaissance Services booth. He apparently wasn’t in the market for short-run legacy parts for his aircraft, so he didn’t appear to be all shook up.

“There was also a Dolly Parton impersonator!” Deptowicz said cheerfully. Pressley confirmed her sighting with a chuckle. If the Dolly double was looking for rapid production of legacy parts, Rick and Don could have told her Renaissance Services’ people would work on her project much more than just 9 to 5.

Click here to access info about Renaissance Services’ rapid parts casting and reverse engineering solutions.

For further information about any of Renaissance Services’ products or services, please contact Rick Pressley at (937) 586-7277 or email Renaissance Services at [email protected]