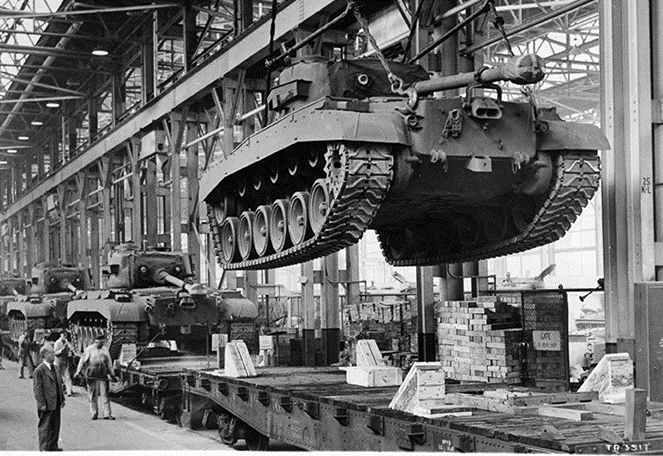

Sustaining DoD weapon systems depends on spare and replacement parts, many requiring highly specialized manufacturing processes. As equipment ages, maintaining operational readiness intensifies, especially when the demand for low-volume castings are no longer supported by original production lines.

Why Low-Volume Castings Matter

- Aging Inventory & Parts Obsolescence: Many weapon systems remain in service well beyond their original design lifespans. As suppliers exit due to low demand, sourcing replacement parts – often unique metal castings – becomes increasingly difficult. In some cases, the only way to source these parts is through short-run or even single-piece custom casting jobs.

- Weapon System Readiness: Without reliable access to replacement castings, readiness of critical platforms suffers. Mission-capable rates decline when even minor components are unavailable, threatening defense readiness and national security.

- Supply Chain Vulnerability: The domestic casting industry, particularly small foundries, faces capacity and equipment challenges. Most U.S. foundries are small businesses, yet the defense sector often requires short-run, high-precision jobs that these businesses are uniquely positioned to provide—if the infrastructure and incentives exist to support them.

Challenges in Producing Low-Volumes

- High Setup and Tooling Costs: Traditional casting relies on molds and dies, which can be prohibitively expensive to manufacture and store for low-volume needs. For small batch requirements, the per-part cost skyrockets, discouraging suppliers from taking on jobs unless prices can be raised significantly.

- Quality Demands: Defense castings must meet stringent standards, often exceeding those in commercial applications. Even minor flaws can jeopardize safety and mission effectiveness, adding to cost, complexity, and lead times.

- Fragmented Supply Base: Many capable suppliers are small, specialized, or lack digital readiness. This fragmentation in the supply chain often makes it hard for the DoD to identify, coordinate, and qualify vendors able to fulfill these niche orders reliably and securely.

Modern Solutions & The Way Forward

- Advanced/Additive Manufacturing: The adoption of 3D-printing and digital mold-making is beginning to offer scalable solutions for low-quantity casting needs. These technologies allow for rapid prototyping, digital storage of designs, and just-in-time production of molds and castings without the overhead of traditional tooling and warehousing.

- Partnerships and Investment: Sustaining and modernizing the industrial base requires targeted investment in both public depots and private foundries, especially small businesses. The Defense Department’s initiatives in advanced manufacturing and supplier matchmaking are key to strengthening future resilience.

- Strategic Planning: A long-term vision for the sustainment industrial base must articulate clear requirements, support capability development in small-batch production, and ensure stable funding so companies can equip themselves to respond to both routine maintenance and urgent operational needs.

Tackling the challenge of small-batch castings is key to keeping both modern and legacy weapon systems mission-ready. Meeting this need takes fresh manufacturing ideas, supportive policies, and steady investment in America’s defense industrial base. DoD and industry must work together so hard-to-source castings stay available, no matter the production size or system age.

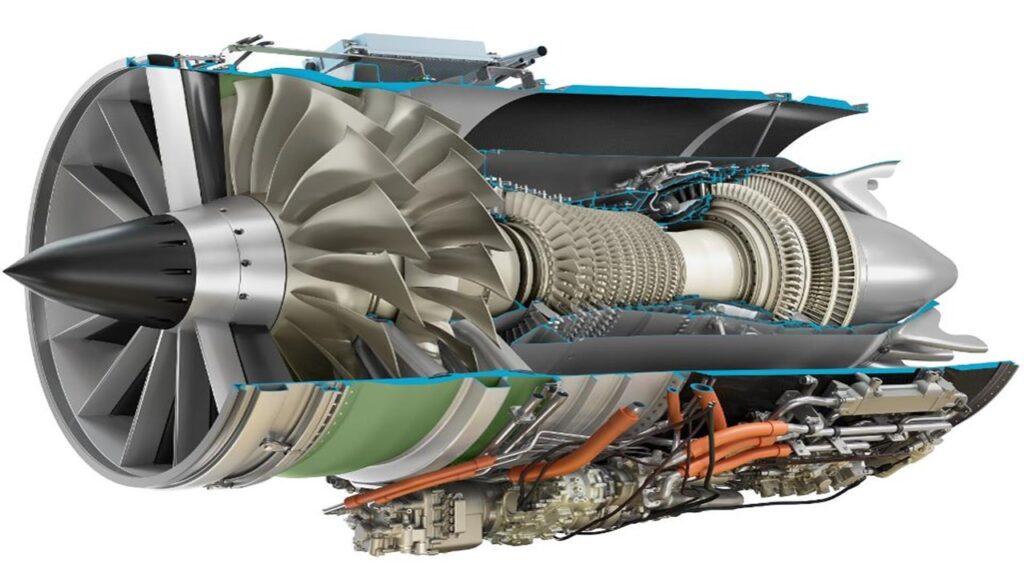

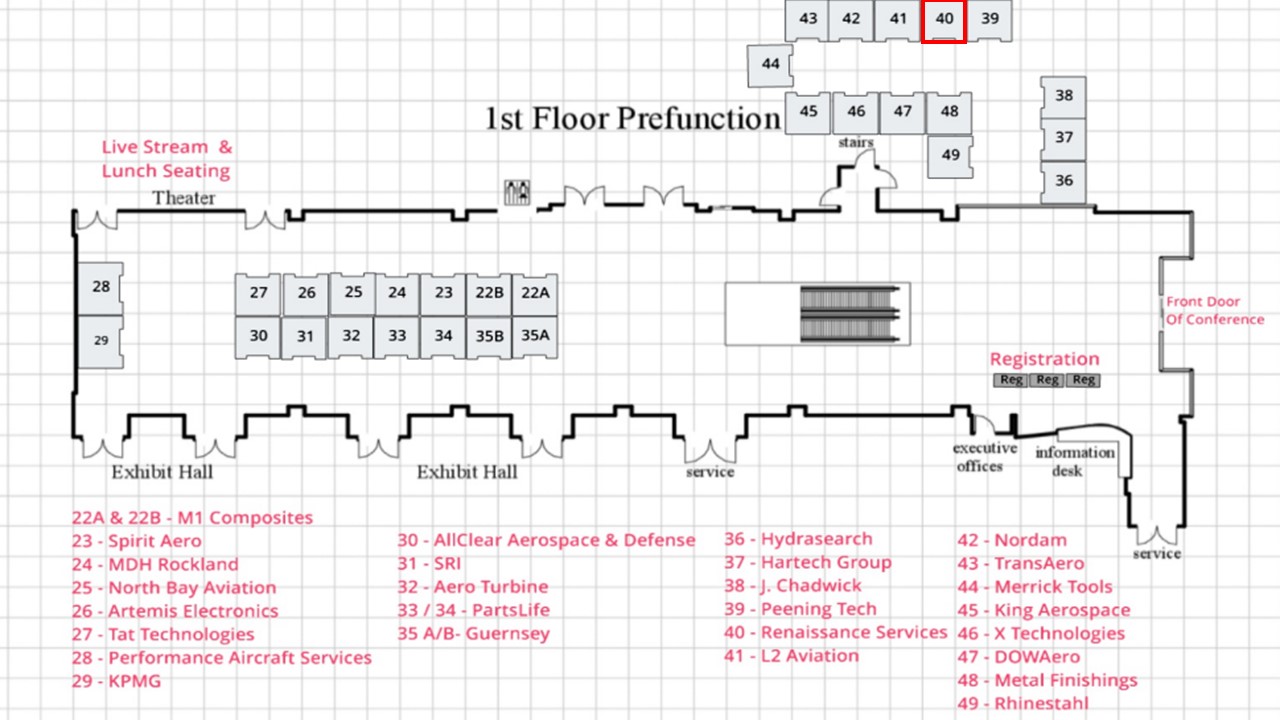

Don Deptowicz, left, explained how the Renaissance Services team was able to produce such a quality rotor quickly.

Don Deptowicz, left, explained how the Renaissance Services team was able to produce such a quality rotor quickly.

Olvera Street entrance. Olvera Street and Los Angeles started in 1781.

Olvera Street entrance. Olvera Street and Los Angeles started in 1781.